Fluidized IQF freezers product description :

FSLD series fluidized bed IQF freezers use of advanced technology, Fluidized IQF freezer is the most suitable for vegetables, fruits such as peas, sweet corn, carrot or dice, caultiflower sheet like frozen equipment, shrimp, seafood is also very effective. In general, it is ideal for any smaller size and large-capacity food.

The main features of FSLD series fluidized IQF freezer:

1.The internal and external structures of the warehouse are made of food grade stainless steel SUS304, all welded by argon arc welding, and the welded joints are treated with acid pickling. (Excluding standard and special components such as reducers and motors).

2. Design process structure parameters based on the characteristics of frozen products, and design an evaporator with a large effective surface area; Adopting a large spacing aluminum alloy finned tube group and variable blade spacing design to reduce the temperature difference between the evaporator and the warehouse, the design selection is calculated based on the evaporation temperature of -42 degrees Celsius.

Adequate evaporation area, high heat transfer efficiency, fully considering the influence of incoming and outgoing temperatures, designed to delay frosting and extend the working time of the quick freezing machine.

3. The evaporator is equipped with an efficient, low-noise, waterproof, moisture-proof, and low-temperature vortex fan.

4. Using the principle of fluidized bed with -35 ℃ temperature inside the warehouse and air blowing under the tunnel, as well as the vibration device in the surface freezing section, the frozen product is lowered to -18 ℃ under the joint action of suspension and variable frequency conveyor belt, uniformly and quickly freezing the individual units, and automatically dropping the material after shipment.

5. The organic combination of evaporator, fan, air guide device, and vibration device forms a uniform and stable frozen product suspension and a fluidized bed with negative feedback for multi-directional air flow to individual units, making the freezing of individual units of frozen products faster and of uniform quality;

6. Adopting an external centralized water valve to control uniform water flushing frost, prevent bacterial growth, maintain cleanliness and hygiene, and meet food hygiene requirements. Install a welded stainless steel large water tray in the quick freezing room; The warehouse is equipped with electrically heated maintenance doors, and all corners of the quick freezing machine are easy to clean and maintain; Except for the slow operation of the mesh belt, all other transmission devices are located inside the insulation cover, which is easy to disassemble and assemble; Set up emergency stop safety buttons and safety warning signs; The overall setting of the quick freezing machine is adjustable horizontally up and down.

FSLD1000 Fluidized IQF FREEZER TECHNICAL PARAMETERS

Item | FSLD1000( frozen cubed mangoes) |

Product | Frozen cubed mangoes |

Capacity | 1000kg/h |

In/Out Temp. | +15℃ to -18℃ |

Freezer Temp. | -35℃ |

In/Out Time | 6-30min |

Refrigerant | R404A/R507 |

Consumption | 170kw |

Freezing Container Thickness | 150mm |

Product Height | ≤100mm |

Belt Width | 1200mm |

Product Input Conveyor/Output Conveyor | 1000mm/500mm |

Water Input Pressure | ≥3 kg/cm2 |

Freezer Power | 38.2KW |

Freezer Size(L*W*H) | 11500×4200×3000mm |

Freezer Body Material | Duplex stainless steel polyurethane insulation board density or 40 kg/m3, the thickness of 150 mm, 304 stainless steel outer plate thickness more than 0.8/0.5mm |

Main Electric Brand | Schneider(France) and DLX etc well-konwn brand |

Belt and Speed | Food-grade stainless steel belt; Frequency conversion stepless speed regulation |

Slide Track Material | Ultrahigh molecular polyethylene material. |

Internal Structure | All made of 304 Stainless Steel Material, Argon arc welding |

Evaporator | Effective from large aluminum finned tube set, stainless steel panel stent |

Fan and Motor | Aluminum alloy stainless steel duct fan low noise and waterproof electric power consumption |

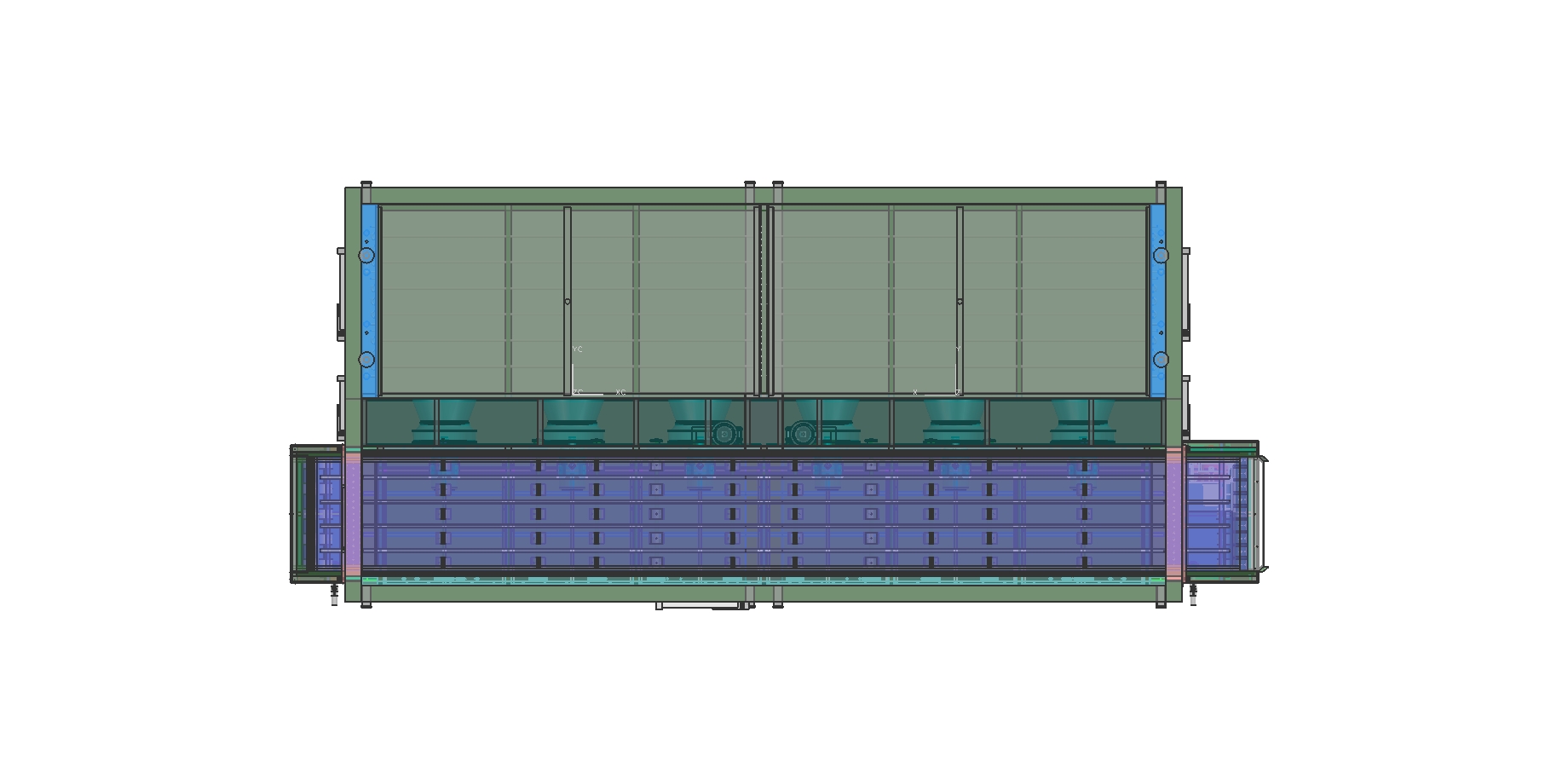

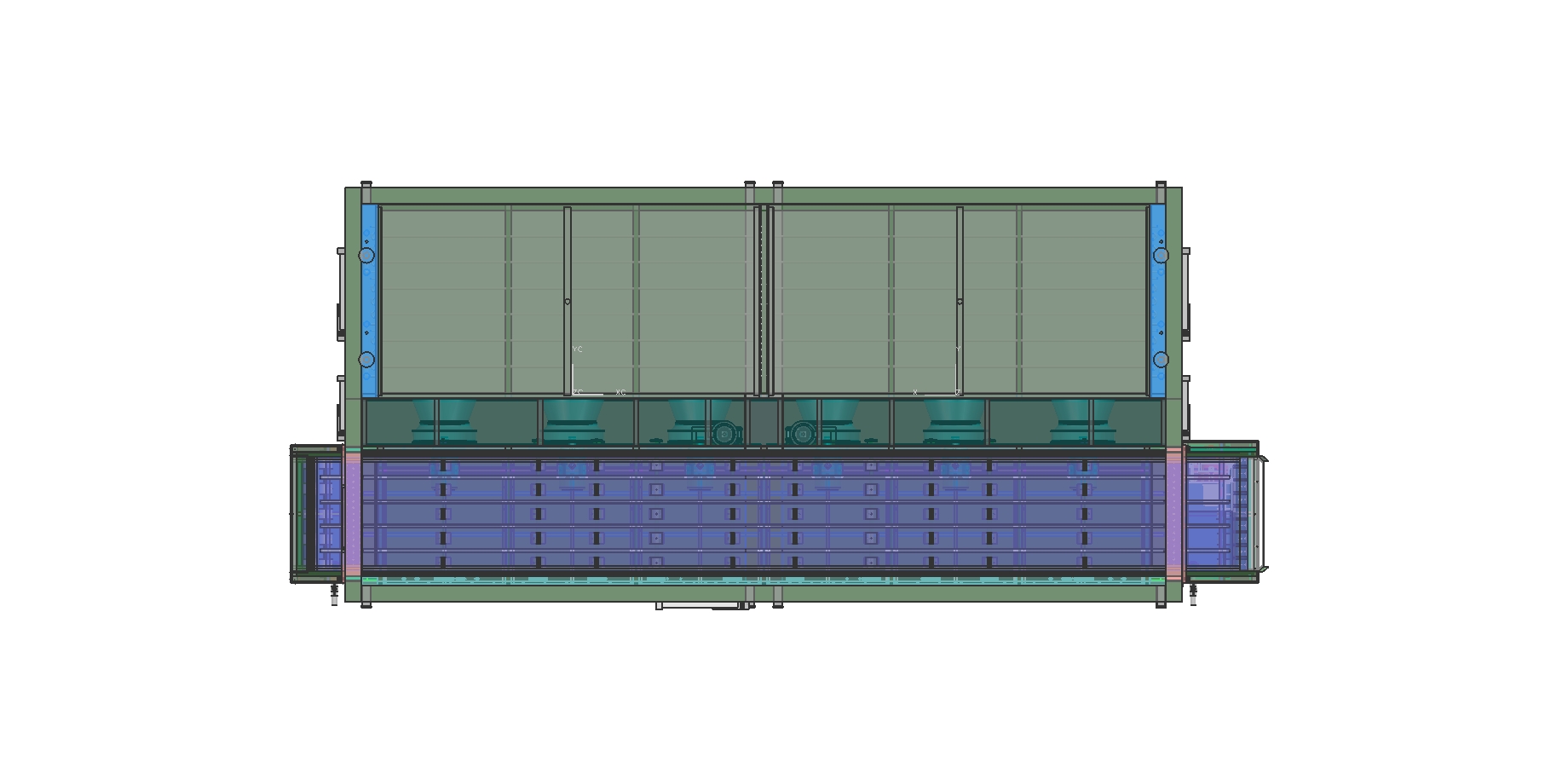

Fluidized IQF freezing structure diagram

Fluidized IQF freezing structure diagram