10T/24h fresh water flake ice machine list

1.) Ice flake machine parts list

NO. | Product name | Brand | Origin | Material |

One | Ice generator |

1 | Evaporator | FST | China | Q235 Carbon steel |

2 | Reducer | KOKI | Taiwan, China | Motor: 0.75KW |

3 | Circulating water pump | FST | China | Motor: 0.37kw |

4 | Infrared switch | Rico | China |

|

5 | Water level switch | Fast | China |

|

6 | Water tank | FST | China | SUS 304 |

7 | Ice skate | FST | China | SUS 304 |

8 | Bearing | AKG | German |

|

9 | Salt water pump | RDOSE | German | 0.016KW |

| Top base | FST | China | ZL301 |

| Pedestal | FST | China | ZL301 |

Two | Refrigerating system |

1 | Compressor | BITZER | German | 2 sets in Parallel (6HE-28Y-40P×2) |

2 | Condenser | FST | China | Water cooling |

3 | Expansion valve | DAFOSS | Denmark |

|

4 | Dry filter | ALCO | America |

|

5 | Oil separator | D&F | Tianjin, China |

|

6 | Oil filter | D&F | Tianjin, China |

|

7 | Oil sight glass | ALCO | America |

|

8 | Backing gas filter cartridges | D&F | Tianjin, China |

|

9 | Liquid-vapor separator | D&F | Tianjin, China |

|

10 | Solenoid valve | Castel | Italy |

|

11 | Vibration absorber | Hanlishi | Korea |

|

12 | High & Low Pressure Controller | DANFOSS | Denmark |

|

13 | High & low pressure gauge | Refco | Italy |

|

14 | Oil pressure gauge | Refco | Italy |

|

15 | Oil pressure controller | BITZER | German |

|

16 | Water tower & cooling pump | Liangyan | China |

|

Three | Control system |

1 | Electricity box | FST | China |

|

2 | Programmable controller (PLC) | LG | Korea |

|

3 | A.C. contactor | LG | Korea |

|

4 | Thermal Overload Relay | LG | Korea |

|

5 | Phase protector | Songling | Taiwan, China |

|

6 | Air switch | CHINT | France |

|

7 | Touch screen | Kunlun Tongtai | Beijing, China |

|

Four | Ice storage system |

1 | Ice storage room | FST | Tianjin, China | Carbon steel for both side |

2 | Ice cart | FST | Tianjin, China | SUS304 |

3 | Ice scoop | FST | Tianjin, China | Engineering plastic |

2.) Technical parameters:

1 | Ice output | 10T/24h |

2 | Total weight | 1760kg |

3 | Flake ice machine size | 2530*1830*1820mm |

Ice room size after assembling | 2600*2500*2200 mm (Door size: W800*H1800) |

Water tower size | Ø1830*1850 mm |

Total net size for installation | 5000(L)*2500(W)*5000(H) mm |

4 | Ice thickness | 1.5mm-2.3mm |

5 | Refrigerant | R404A |

6 | Refrigerating capacity | 65kw |

7 | Evaporator materials | Carbon steel (Interior: Q235 carbon steel; Exterior surface: SUS 304; Insulation layer: Polyurethane) |

8 | Evaporation temp. | -22℃ |

9 | Condensing temp. | +40℃ |

10 | Standard Inlet water temp. | +18℃ |

11 | Standard ambient temp. | +25℃ |

12 | Feed water pressure | 0.1MP-0.5MP |

13 | Installation total power | 45.5kw |

14 | Power supply | 3P/380V(50Hz) |

15 | Ice temperature | -5∽-8℃ |

16 | Cooling form | Water-cooling |

17 | Water feeding type | Fresh water |

18 | Water pipe size | 1/2" |

19 | Noise | ≤60dB |

3.) Installation requirements

(1) Voltage: 3P 380V 50 HZ; 3 phase with 5 wires;

(2) Water resource:Clean water, tap water is ok, within 1.5 meters from the ice machine;

(3) Installation place should be with good ventilation, away from dissipation devices and protected from direct splar radiation & rain , standard working environment temperature: 5℃~35℃;

(4) The ground should be level with good drainage system;

(5) Water pressure: 0.1MPa~0.6MPa;

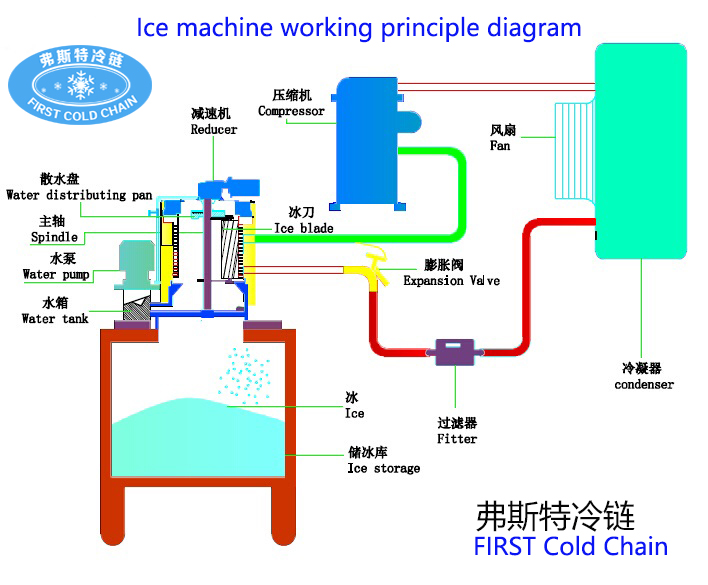

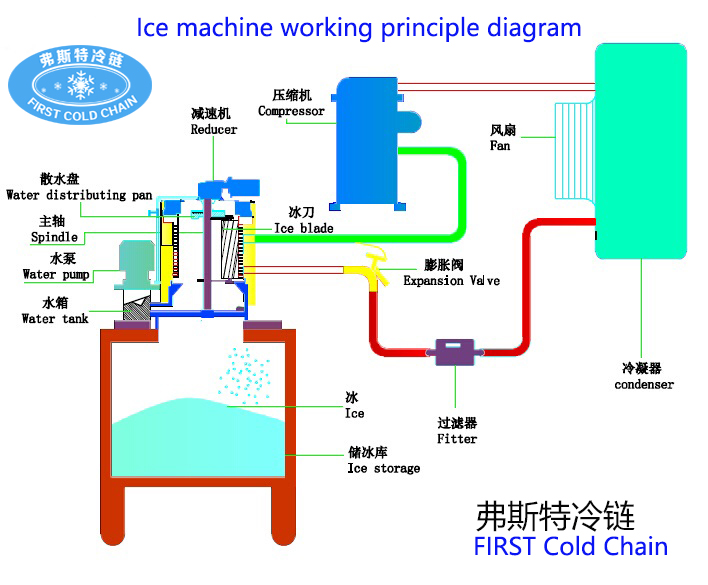

(6) Space for installation: checking below picture