Fluidized IQF freezers product description :

First Cold Chain brand efficient fluidized bed freezer, designed for quick freezing of various food products, particularly French fries.

This freezer utilizes a 2-stage or multi-stage structure along with a vibration device to easily achieve individual freezing of products.

The rapid freezing process ensures high product quality, allowing the frozen items to maintain their original texture and taste after thawing.

Experience superior freezing performance with our fluidized bed freezer.

FSLD1500 Fluidized IQF freezer parameter:

Item | FSLD1500(fries) |

Product | fries |

Capacity | 1500kg/h |

In/Out Temp. | +15℃ to -18℃ |

Freezer Temp. | -35℃ |

In/Out Time | 6-30min |

Refrigerant | R717 |

Consumption | 230kw |

Freezing Container Thickness | 150mm |

Product Height | ≤100mm |

Belt Width | 1200mm |

Product Input /Output Conveyor | 1000 mm/500mm |

Water Input Pressure | ≥3 kg/cm2 |

Freezer Power | 62.5KW |

Freezer Size(L*W*H) | 15500×4000×3500mm |

Freezer Body Material | Duplex stainless steel polyurethane insulation board density or 40 kg/m3, the thickness of 150 mm, 304 stainless steel outer plate thickness more than 0.5 mm |

Main Electric Brand | Schneider(France) and DLX etc well-known brand |

Belt and Speed | Food-grade stainless steel belt; Frequency conversion stepless speed regulation |

Slide Track Material | Ultrahigh molecular polyethylene material. |

Internal Structure | All made of 304 Stainless Steel Material, Argon arc welding |

Evaporator | Effective from large aluminum finned tube set, stainless steel panel stent |

Fan and Motor | Aluminum alloy stainless steel duct fan low noise and waterproof electric power consumption |

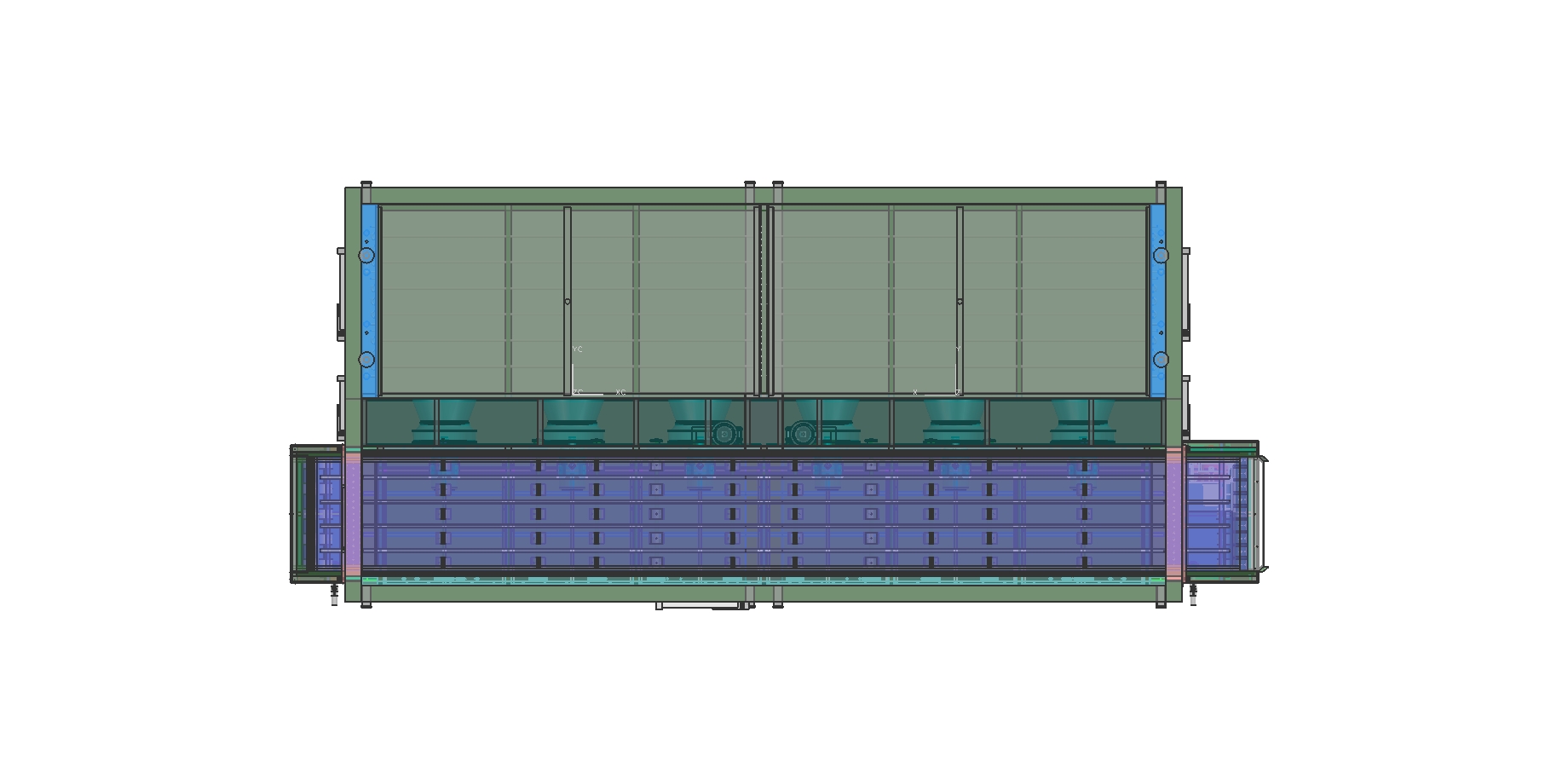

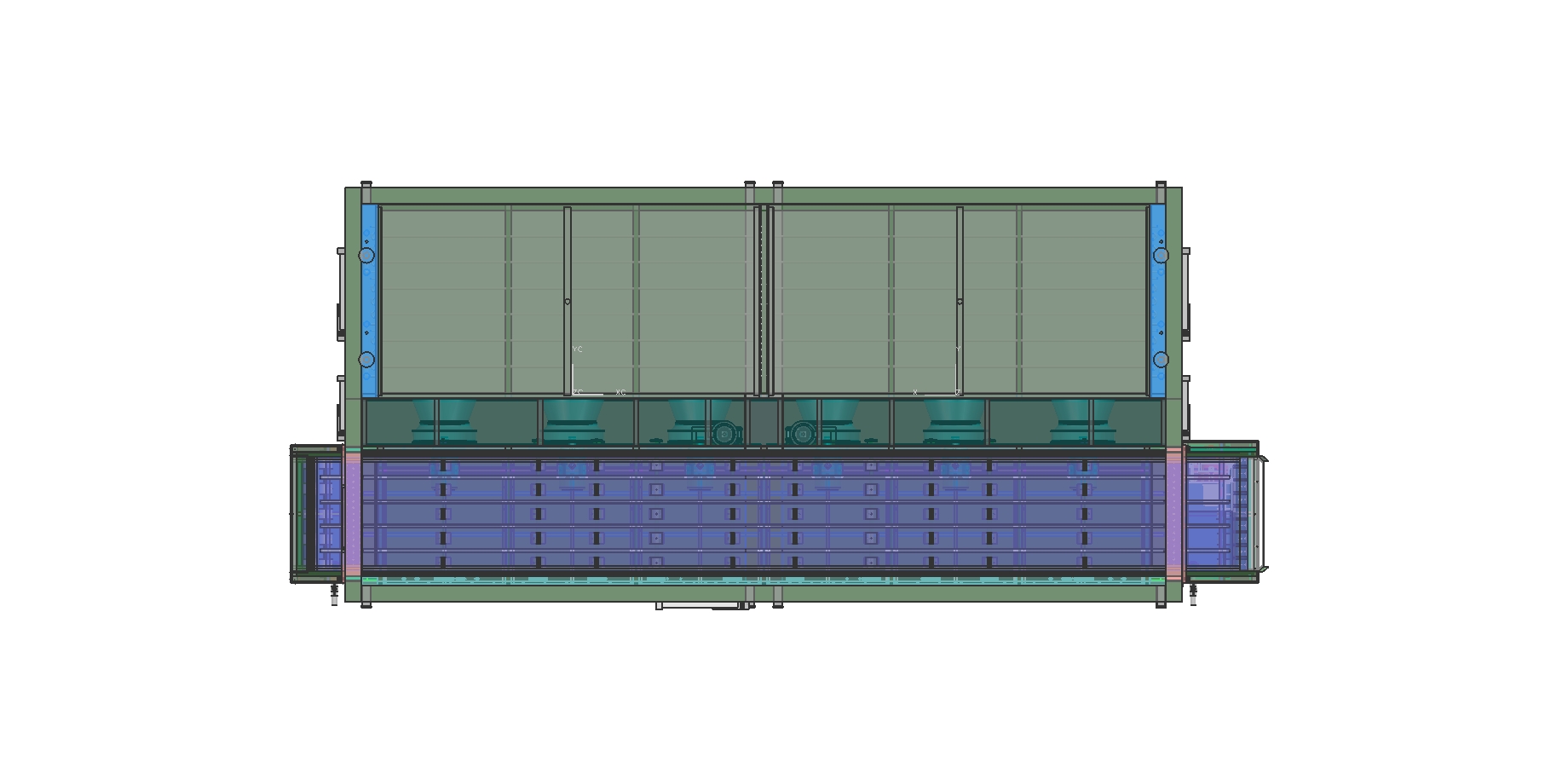

Fluidized bed IQF freezing structure diagram

Fluidized bed IQF freezing structure diagram

Fluidized bed IQF

Fluidized bed IQF