Introducing our Tunnel Freezer for Frozen Cheese, a state-of-the-art freezing solution designed to meet the highest industry standards. With a professional tone, we present the key features of this product.

First Cold Chain's Tunnel Freezer for Frozen Cheese is specifically engineered to freeze cheese, ensuring that it reaches its desired consistency in a shorter time frame. This efficient freezing process allows for a more streamlined packaging and storage process, ultimately improving overall productivity.

One of the standout features of our Tunnel Freezer is its ability to freeze cheese while still on the tray. This unique capability eliminates the need for additional handling, saving valuable time and resources. By freezing the cheese directly on the tray, the product retains its shape and quality, resulting in a visually appealing final product.

Customization is a key aspect of our Tunnel Freezer. We offer a wide range of production capacities, ranging from 100kg/h to 2000kg/h, allowing you to choose the option that best suits your specific needs. For the purpose of this description, we will focus on the 1000kg/h production capacity.

With a production capacity of 1000kg/h, our Tunnel Freezer for Frozen Cheese ensures efficient and consistent freezing of your cheese products. This high production rate allows for increased output, meeting the demands of even the busiest production facilities.

In addition to its impressive freezing capabilities, our Tunnel Freezer for Frozen Cheese is built with durability and reliability in mind. Crafted from high-quality materials, this freezer is designed to withstand the rigors of daily use, ensuring long-lasting performance and minimal downtime.

Investing in our Tunnel Freezer for Frozen Cheese means investing in a top-of-the-line freezing solution that will enhance your cheese production process. With its ability to freeze cheese on trays, customizable production capacities, and robust construction, this freezer is the perfect addition to any cheese manufacturing facility.

Choose our Tunnel Freezer for Frozen Cheese and experience the benefits of efficient freezing, improved packaging, and increased productivity.

Contact us today to learn more about how our freezer can revolutionize your cheese production process.

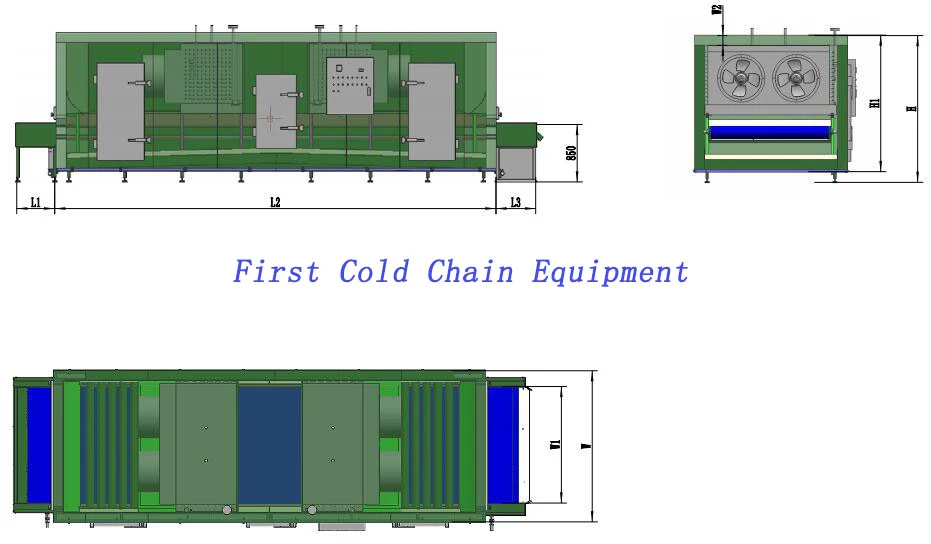

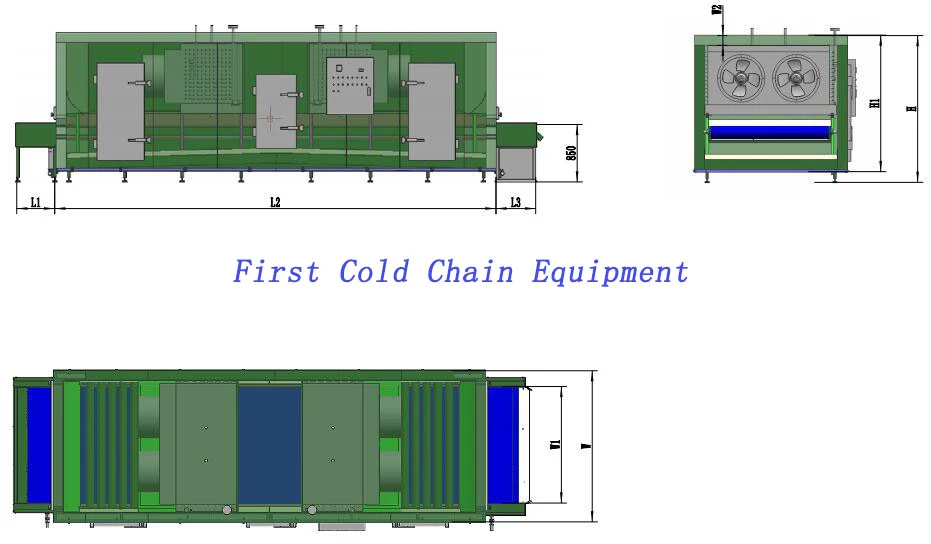

FSW1000 TUNNEL FREEZER TECHNICAL PARAMETERS

Item | FSW1000( Frozen cheese ) |

Product | Frozen cheese |

Capacity | 1000kg/h |

In/Out Temp. | +15℃ to -18℃ |

Freezer Temp. | -38℃ |

In/Out Time | 10-50min |

Refrigerant | R507 |

Consumption | 170kw |

Freezing Container Thickness | 150mm |

Product Height | ≤100mm |

Belt Width | 2500mm |

Product Input /Output Conveyor | 1000 /800mm |

Water Input Pressure | ≥3 kg/cm2 |

Freezer Power | 19.8KW |

Freezer Size(L*W*H) | 19800×3000×2500mm |

Freezer Body Material | Duplex stainless steel polyurethane insulation board density or 40 kg/m3, the thickness of 150 mm, 304 stainless steel outer plate thickness more than 0.8 mm |

Main Electric Brand | Schneider(France) |

Belt and Speed | Food-grade stainless steel mesh belt; Frequency conversion stepless speed regulation |

Slide Track Material | Ultrahigh molecular polyethylene material. |

Internal Structure | All made of 304 Stainless Steel Material, Argon arc welding |

Evaporator | Effective from large aluminum finned tube set, stainless steel panel stent |

Fan and Motor | Aluminum alloy stainless steel duct fan low noise and waterproof electric power consumption |