| Availability: | |

|---|---|

| Quantity: | |

FYW400

FST

FST400

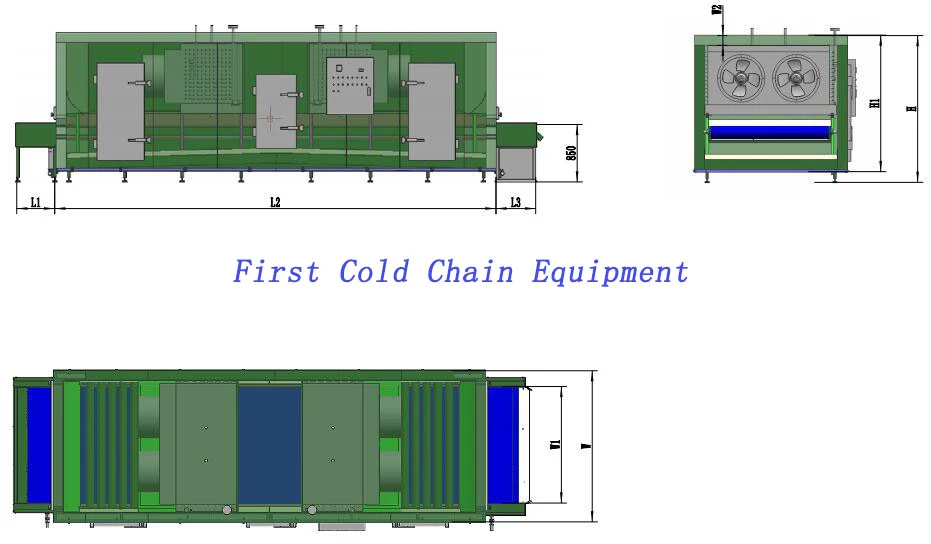

Tunnel Cooler product description

The Tunnel cooler is specifically designed for rapidly cooling fast food such as rice dishes. With its high cooling speed and industrial-grade efficiency, this machine is able to quickly bring the temperature of the product from 50 degrees down to 0-5 degrees.

This rapid cooling process is beneficial for the storage and transportation of the product, ensuring its freshness and quality. Additionally, the quick cooling helps to maintain the taste of the product and inhibit the growth of bacteria, guaranteeing food safety and quality.

The customer deatils request:

Cooling food : rice with package . the package size: 20*35*5cm

Inter/out temperature :+50~0℃ ,the product weight :1.4kg/unit

Cooling time: In 15 to 75 min

The capacity: 400kg/h.

FYW400 TUNNEL COOLER TECHNICAL PARAMETERS

Item | FYW400( Rice cooling) | |

Product | Rice | |

Capacity | 400kg/h | |

In/Out Temp. | +50℃ to 0℃ | |

Freezer Temp. | -15 t o -20℃ | |

In/Out Time | 15-75min | |

Refrigerant | R404A | |

Consumption | 30KW | |

Freezing Container Thickness | 100mm | |

Product Height | ≤100mm | |

Belt Width | 1800mm | |

Water Input Pressure | ≥3 kg/cm2 | |

Freezer Power | 5.15 KW | |

In/out Guard Length | 600/600 mm | |

In total Freezer Size(L*W*H) | 11200×2200×2200mm | |

Freezer Body Material | Duplex stainless steel polyurethane insulation board density or 40 kg/m3, the thickness of 100 mm, 304 stainless steel outer plate thickness more than 0.8 mm | |

Main Electric Brand | Schneider(France) | |

Belt and Speed | Food-grade stainless belt; Frequency conversion step less speed regulation | |

Slide Track Material | Ultrahigh molecular polyethylene material. | |

Internal Structure | All made of 304 Stainless Steel Material, Argon arc welding | |

Evaporator | Effective from large aluminum finned tube set, stainless steel panel stent | |

Fan and Motor | Aluminum alloy stainless steel duct fan low noise and waterproof electric power consumption | |

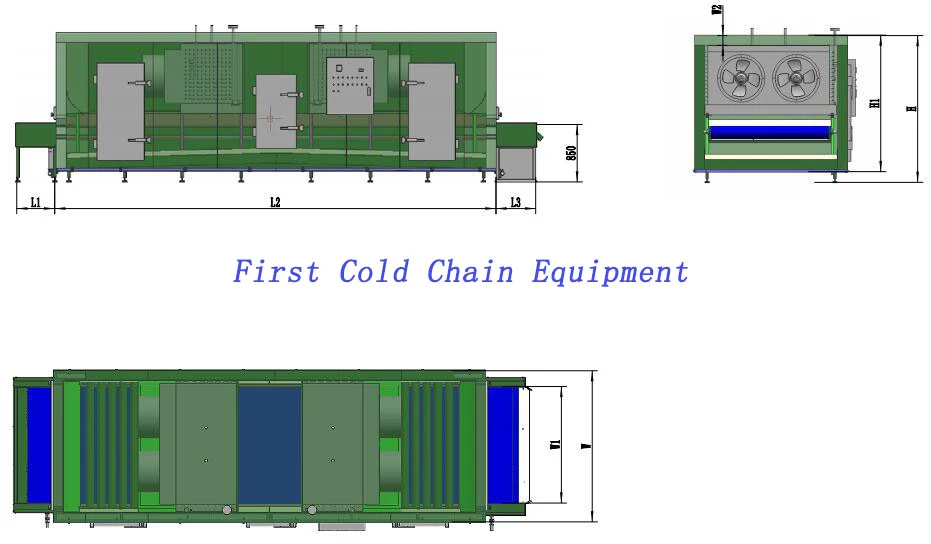

Tunnel Cooler product description

The Tunnel cooler is specifically designed for rapidly cooling fast food such as rice dishes. With its high cooling speed and industrial-grade efficiency, this machine is able to quickly bring the temperature of the product from 50 degrees down to 0-5 degrees.

This rapid cooling process is beneficial for the storage and transportation of the product, ensuring its freshness and quality. Additionally, the quick cooling helps to maintain the taste of the product and inhibit the growth of bacteria, guaranteeing food safety and quality.

The customer deatils request:

Cooling food : rice with package . the package size: 20*35*5cm

Inter/out temperature :+50~0℃ ,the product weight :1.4kg/unit

Cooling time: In 15 to 75 min

The capacity: 400kg/h.

FYW400 TUNNEL COOLER TECHNICAL PARAMETERS

Item | FYW400( Rice cooling) | |

Product | Rice | |

Capacity | 400kg/h | |

In/Out Temp. | +50℃ to 0℃ | |

Freezer Temp. | -15 t o -20℃ | |

In/Out Time | 15-75min | |

Refrigerant | R404A | |

Consumption | 30KW | |

Freezing Container Thickness | 100mm | |

Product Height | ≤100mm | |

Belt Width | 1800mm | |

Water Input Pressure | ≥3 kg/cm2 | |

Freezer Power | 5.15 KW | |

In/out Guard Length | 600/600 mm | |

In total Freezer Size(L*W*H) | 11200×2200×2200mm | |

Freezer Body Material | Duplex stainless steel polyurethane insulation board density or 40 kg/m3, the thickness of 100 mm, 304 stainless steel outer plate thickness more than 0.8 mm | |

Main Electric Brand | Schneider(France) | |

Belt and Speed | Food-grade stainless belt; Frequency conversion step less speed regulation | |

Slide Track Material | Ultrahigh molecular polyethylene material. | |

Internal Structure | All made of 304 Stainless Steel Material, Argon arc welding | |

Evaporator | Effective from large aluminum finned tube set, stainless steel panel stent | |

Fan and Motor | Aluminum alloy stainless steel duct fan low noise and waterproof electric power consumption | |

Contact Person : SUNNY SUN

Phone : +86-18698104196 / 13920469197

Whatsapp/Facebook : +86-18698104196

Wechat/Skype : +86-18698104196

E-mail : soleado.first@foxmail.com

sunny@fstcoldchain.com