Introducing our top-notch Ice Flake Maker:

The Ice Flack Maker specifically engineered to meet various needs in preserving and transporting seafood, fruits, and vegetables. With its user-friendly operation and impressive ice-making speed, this machine is essential for businesses aiming to uphold the freshness and excellence of their perishable goods.

Our Ice Flake Maker is constructed to fulfill the specific requirements of our esteemed clients. Whether you require it for small-scale operations or large-scale production, this machine can be tailored to fit your needs. Currently, we offer a production capacity of 5 tons per day, ensuring a dependable and consistent supply of ice flakes.

Here are some key factors to consider:

1. Efficiency: Our Ice Flake Maker is designed to deliver outstanding ice-making efficiency, guaranteeing a continuous provision of top-quality ice flakes to meet your demands.

2. Convenience: Operating this machine is a breeze, thanks to its user-friendly interface and instinctive controls. You can effortlessly monitor and adjust the ice-making process to achieve the desired outcomes.

3. the capacity from 200kg/24H to 20t/24H

Flake ice maker machine 1T/24h |

No | Name | Model |

|

1 | Daily capacity | 1000KG/24h |

|

2 | Refrigeration capacity | 6kw |

|

3 | Evaporating temp | -20℃ |

|

4 | Condensing temp | 40℃ |

|

5 | Environment temp | 30℃ |

|

6 | Water supply temp | 22℃ |

|

7 | Installation power | 23.12KW |

|

8 | Compressor power | 20KW |

|

9 | Reducer power | 0.37KW |

|

10 | Water pump power | 0.18KW |

|

11 | Salt pump power | 0.016KW |

|

12 | Power supply | 3P-380V~420V-50Hz |

|

14 | Gas | R404A/R507A |

|

15 | Ice temperature | -7℃ |

|

16 | Water pipe size | 1/2" |

|

17 | Net weight | 765KG |

|

18 | Ice thickness | 1.8MM-2.8MM |

|

19 | Machine size mm | 1320*1580*1980 |

|

FIM1 Flack ice maker Parts list |

Name | Brand | Model | Material | Place |

NO. | Evaporator parts |

1 | Evaporator | FST | 1T | Carbon steel | CHINA |

2 | Reducer | GONGJI | TKVWEQ100 | IRON | CHAIN |

3 | Water pump | CHUANGSH | PA-1/4FA | PP | CHINA |

4 | Sensor | RUIKE | MF-5KP2 |

| TAIWAN |

5 | Water level controller | FST | FAST-32LP |

| CHINA |

6 | Salt water pump | IWAKI |

|

| JAPAN |

| Refrigeration unit |

1 | Compressor | danfoss | 1 PCS | 5P | danmark

|

2 | Condenser | GELIN | Air cooled |

| CHINA |

AIR COOLER | 4*0.42kw | 1.68kw | CHINA |

3 | Filter | ALCO | FD-487-T |

| USA |

4 | Expansion valve | ALCO | TES 5-7.2 |

| USA |

5 | L-P controller | DANFOSS | KP1 |

| DANMARK |

6 | H-P controller | DANFOSS | KP5 |

| DANMARK |

7 | Gas separator | DANFOSS | FA210 |

| DANMARK |

8 | Oil separator | DANFOSS | AW55901 |

| DANMARK |

9 | Solenoid valve | DANFOSS |

|

| DANMARK |

| Controller system |

1 | PLC | LG |

|

| KR |

2 | Contactor |

|

|

| CHINA |

3 | Therme relay |

|

|

| CHINA |

4 | Phase protector |

|

|

| CHINA |

5 | Breaker |

|

|

| CHINA |

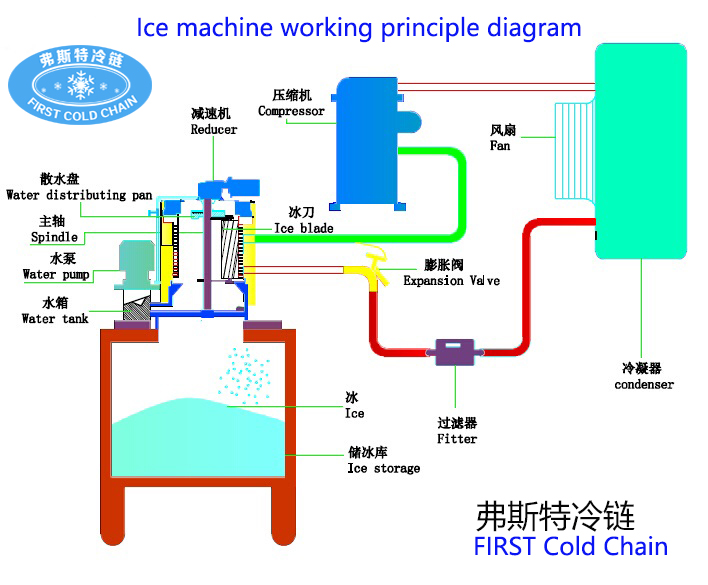

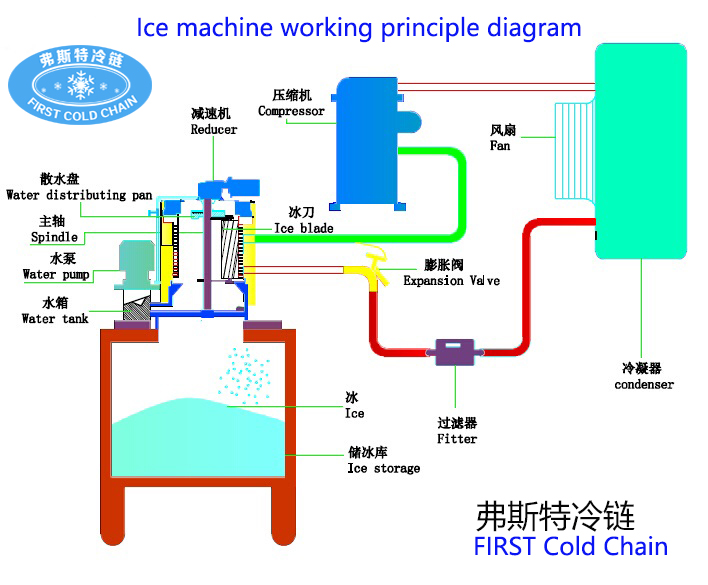

Flake ice drum structure with material

Item | Material |

Freezing surface | Carbon steel with chromed |

Base | SUS 304 |

Top lid | Carbon steel |

Top cover | Carbon steel |

Axis | SUS 304 |

Ice blade | SUS 304 |

Water distribution pan | SUS304 |

Water block plate | SUS304 |

Bearing | NSK |

Insulation layer | Polyurethane |

Outer | SUS304 |

Reducer | GONGJI |

Dosing pump | WBM-02-07 |

Water tank | SUS304 |

Water pump | PP |

Bottom frame | SUS 304 |

Installation requirements:

(1) Voltage: 3P 380~420V 50 HZ; 3 phase

(2) Installation place should be with good ventilation, away from dissipation devices and protected from direct splar radiation & rain , standard working environment temperature: 5℃~35℃;

(3) The ground should be level with good drainage system;

(4) Space for installation: checking below picture