FIM15 Flake ice maker machine parameter list

Fresh water flake ice machine: |

Refrigeration system |

1 | Compressor | Bitzer | 70HP | 1 | GERMANY |

2 | Thermoexpension valve | DANFOSS | --- | 4 | DANMARK |

3 | Filter | D&F | --- | 3 | CHINA |

4 | Solenoid valve | DANFOSS | --- | 3 | DANMARK |

5 | Series regenerator | D&F | --- | 1 | CHINA |

6 | Ball valve | OLAB | --- | 3 | LTALY |

7 | Oil separator | D&F | --- | 1 | CHINA |

8 | Economizer | D&F | --- | 1 | CHINA |

9 | Stop valves | AMG | --- | 1 | CHINA |

10 | Stop stop valve | AMG | --- | 1 | CHINA |

11 | Oil temperature controller | SF | --- | 1 | DANMARK |

12 | Temperature control | SF |

| 1 | AMERICA |

13 | H-L pressure controller | DANFOSS | --- | 3 | DANMARK |

14 | Pressure gauge | VAB |

| 3 | CHINA |

15 | Water gauge | DANFOSS | --- | 2 | DANMARK |

16 | Safety Valves | CASTEL |

| 1 | LTALY |

17 | Oil level controller | D&F | --- | 1 | CHINA |

18 | Reservoir | D&F | --- | 1 | CHINA |

19 | Condenser (fin) | D&F | --- | 1 | CHINA |

20 | Condenser fan | WEIGUANG |

| 8 | CHINA |

21 | Oil condenser (fin) | D&F | --- | 1 | CHINA |

22 | Oil condenser fan | WEIGUANG |

| 2 | CHINA |

Electronic controller |

23 | PLC | LG | --- | 1 | KORE |

24 | contactor | LG | --- | 5 | KORE |

25 | Thermal overload relay | LG | --- | 5 | KORE |

26 | Middle relay | CHINT | --- | 5 | CHINA |

27 | Phase protector | CIKACHI | --- | 1 | TAIWAN |

28 | Touch screen | MCGS | --- | 1 | CHINA |

29 | Electric control panel | LIER | --- | 1 | CHINA |

30 | Air switch | LG | --- | 1 | KORE |

3) FST-15T technical parameters:

No | Name | Data |

1 | Output (kg/24h) | 15000 |

2 | Cooling capacity(KW) | 97.5 |

3 | Installation power (KW) | 53 |

4 | Compressor power (HP) | 43.9 (70HP) |

5 | Water source | Fresh water |

6 | Reducer power (KW) | 0.75 |

7 | Water supply pump power (KW) | 0.37 |

8 | Fan power of condenser (KW) | 0.8*8 |

9 | Dosing pump power(KW) | 0.016 |

10 | Compressor head fan power(KW) | 0.42*2 |

11 | Evaporating temp(℃) | -20 |

12 | Condensing temp(℃) | 45 |

13 | Ambient temp(℃) | 35 |

14 | Water supply temp(℃) | 20 |

15 | Power supply | 3P/380V/50Hz |

16 | Water pressure(MPA) | ≤0.6 |

17 | Water consumption (kg/h) | 625 |

18 | Refrigerant | R404A |

19 | Ice temp(℃) | -2~-5 |

20 | Ice thickness(mm) | 1.8~2.2 |

21 | Water pipe diameter | 3/4’’*2 |

22 | Weight(kg) | 2250 |

23 | Unit size(mm) | 4000*2200*2200 |

Item | Material |

Freezing surface of drum | Carbon steel with chromed |

Base | Cast ZN |

Top lip | Cast ZN |

Top cover | Cast ZN |

Axis | SUS304 |

Ice blade | SUS304 |

Water distribution pan | SUS304 |

Water block plate | SUS304 |

Bearing | NSK |

Insulation layer | Polyurethane |

Outer | SUS304 |

Reducer | GONGJI |

Dosing pump | WBM-02-07 |

Water tank | SUS304 |

Water pump | PP |

Bottom of supporting ice machine | Galvanized Carbon steel |

Air cooling condenser | Normal material with painting |

3.) Installation requirements

(1) Voltage: 3P 380V 50 HZ; 3 phase with 5 wires;

(2) Water resource:Clean water, tap water is ok, within 1.5 meters from the ice machine;

(3) Installation place should be with good ventilation, away from dissipation devices and protected from direct splar radiation & rain , standard working environment temperature: 5℃~35℃;

(4) The ground should be level with good drainage system;

(5) Water pressure: 0.1MPa~0.6MPa;

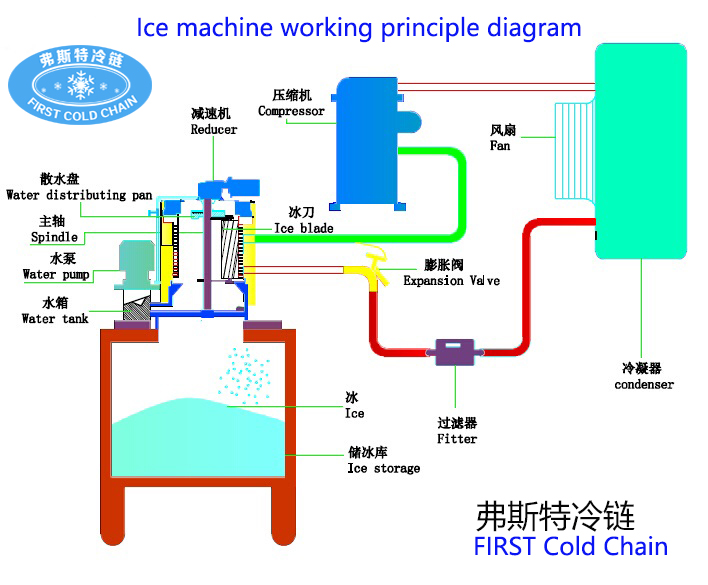

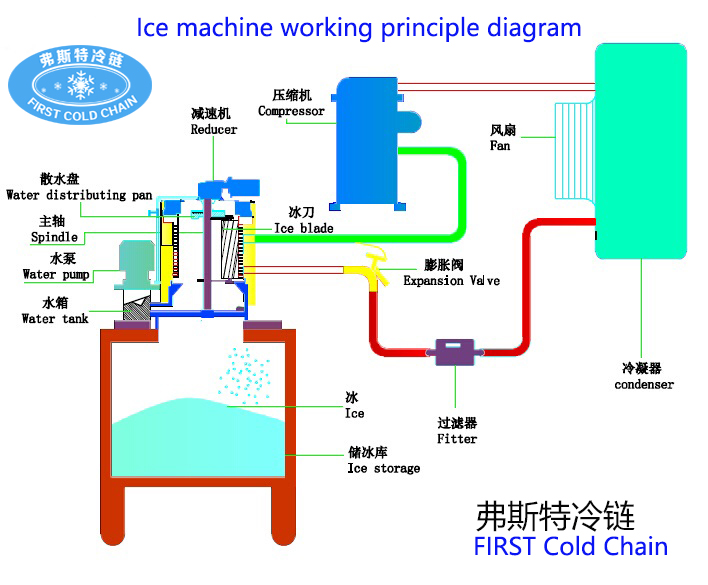

(6) Space for installation: checking below picture